Bryant 330AAV User Manual Page 9

- Page / 12

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

9

35

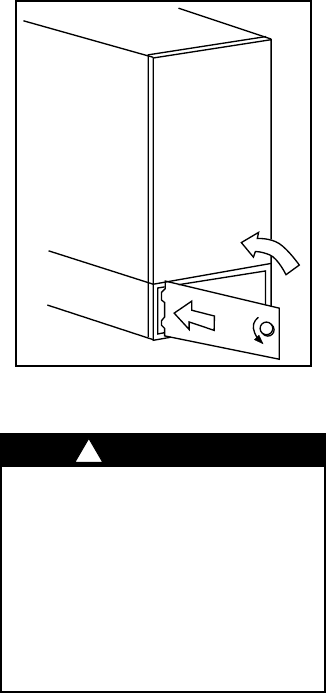

4. Replace the access doors and

restore electrical supply to the

furnace. Be sure bottom door

flange is inside of the furnace cas-

ing. (See Fig. 16 and 17.)

5. Start the furnace and observe its

operation. If possible, watch the

burner flames. Are they burning

bright blue? If not or if you sus-

pect some other malfunction, call

your servicing dealer.

BEFORE YOU REQUEST

A “SERVICE CALL’’

BEFORE YOU CALL FOR

SERVICE, CHECK FOR

SEVERAL EASILY SOLVED

PROBLEMS:

• Check for sufficient airflow. Check

the air filter for dirt. Check for blocked

return-air or supply-air grilles. Be sure

they are open and unobstructed. If this

isn’t the cause of the problem, call your

servicing dealer.

If your furnace isn’t operating at all,

check the following list for easily

solved problems:

• Is your thermostat set above room

temperature? Is the switch in the

HEAT position?

• Is the electrical power supply switch

on? Is the blower access door firmly in

place? Are any fuses blown? (There is a

fuse on the furnace control.) Has a cir-

cuit breaker tripped?

• Is the manual shutoff valve in the gas

supply pipe leading to the furnace

open? Does the lever point in the same

direction that the pipe runs (open)? Or is

it at a right angle to the pipe (closed)?

NOTE:

Before proceeding with the

next checks, turn off the electrical

power supply to the furnace. Remove

access doors.

• Is the control knob or switch on the

gas valve turned to the ON position? If

this or the preceding check shows

an interruption in the gas supply,

make sure the gas has not been shut

off for safety reasons. If nothing else

seems to be wrong, follow the startup

procedures found on pages 4 and 5

of this booklet.

• If for some reason the vent is

blocked, the draft safeguard switch will

shut off the furnace. Reset the switch

by pushing the button located on top

of the switch. See page 2 or 3 for switch

location.

If the switch trips a second time, turn

off the furnace and call for service.

•

DOWNFLOW HORIZONTAL

ONLY—Check the manual reset auxil-

iary limit switch located on the blower

housing. If the blower motor fails, this

switch will shut off the furnace. Reset it

by pushing the button on the switch. If

it trips again, turn off the furnace and

call for service.

• Check the manual reset flame roll-

out switch(es) located near the burn-

ers. If the furnace has experienced a

high-temperature condition due to

inadequate combustion air, these

switches will shut off the furnace.

Reset the switch(es) by pushing the

button on the switch. If the switch trips

a second time, turn off the furnace and

call for service.

• If your furnace still fails to operate,

call your servicing dealer for trouble-

shooting and repairs. Tell your dealer

the model and serial numbers for your

furnace. (You should have them

recorded on page 12 of this booklet.)

By knowing exactly which furnace you

have, the dealer may be able to offer

suggestions over the phone or save

valuable time through knowledgeable

preparation for the service call.

• Your furnace control board has an

LED fault code light that indicates

the furnace status. The LED will flash

short and long flashes. Look through the

sight glass on the furnace door and

determine the code (number

of short and long flashes). Give the

code and furnace model number to

your dealer when you call. By knowing

exactly which furnace you have and

the LED code being displayed, your

dealer can save valuable time through

knowledgeable preparation for the ser-

vice call.

REGULAR DEALER

MAINTENANCE

In addition to the type of routine

maintenance you might be willing to

do, your furnace should be inspected

regularly by a properly trained service

technician. A semiannual inspection

(or annual inspection, at least) should

include the following:

1. Inspection of all flue product

passages including the burners,

heat exchanger, relief box, and

vent pipe.

2. Inspection of all combustion and

ventilation air passages and

openings.

3. Close check of all gas pipes lead-

ing to and inside of your furnace.

4. Inspection, cleaning, and lubrica-

tion (when required) of the

blower motor and wheel.

NOTE: Refer to the unit Service

Procedures for blower motor oiling

information. When required, the

motor must be oiled by a qualified

service technician.

5. Routine inspection and cleaning/

replacement of the air filter.

6. Inspection of all supply- and

return-air ducts for obstructions,

air leaks, and insulation. Any

problems found should be

resolved at this time.

7. Inspect the return-air duct con-

nection(s) at the furnace to

ensure it is physically sound,

sealed to the furnace casing, and

terminates outside the space con-

taining the furnace.

8. Inspection of furnace installation

for proper support and any ob-

vious deterioration of the furnace.

The support must be sound and

WARNING

If holes are found or if the vent

pipe is obstructed or is not

connected, toxic fumes can es-

cape into your home. DO NOT

OPERATE YOUR FURNACE.

Call your dealer for service.

A failure to follow this warning

could result in personal injury

or death.

!

(4 pages)

(4 pages)

Comments to this Manuals