Bryant 355MAV User Manual Page 5

- Page / 20

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

III. CLEANING BURNERS

The following items should be performed by a qualified service

technician. If the burners develop an accumulation of light dirt or

dust, they may be cleaned by using the following procedure:

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Remove burner box cover.

4. Using backup wrench, disconnect gas supply pipe from

furnace gas valve.

CAUTION: ELECTRICAL SHOCK AND UNIT

DAMAGE HAZARD

Failure to follow this caution may result in minor

personal injury or furnace component damage.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation.

5. Remove wires from gas valve. Note location for reassem-

bly.

6. Remove burner box pressure tube from gas valve regulator

fitting.

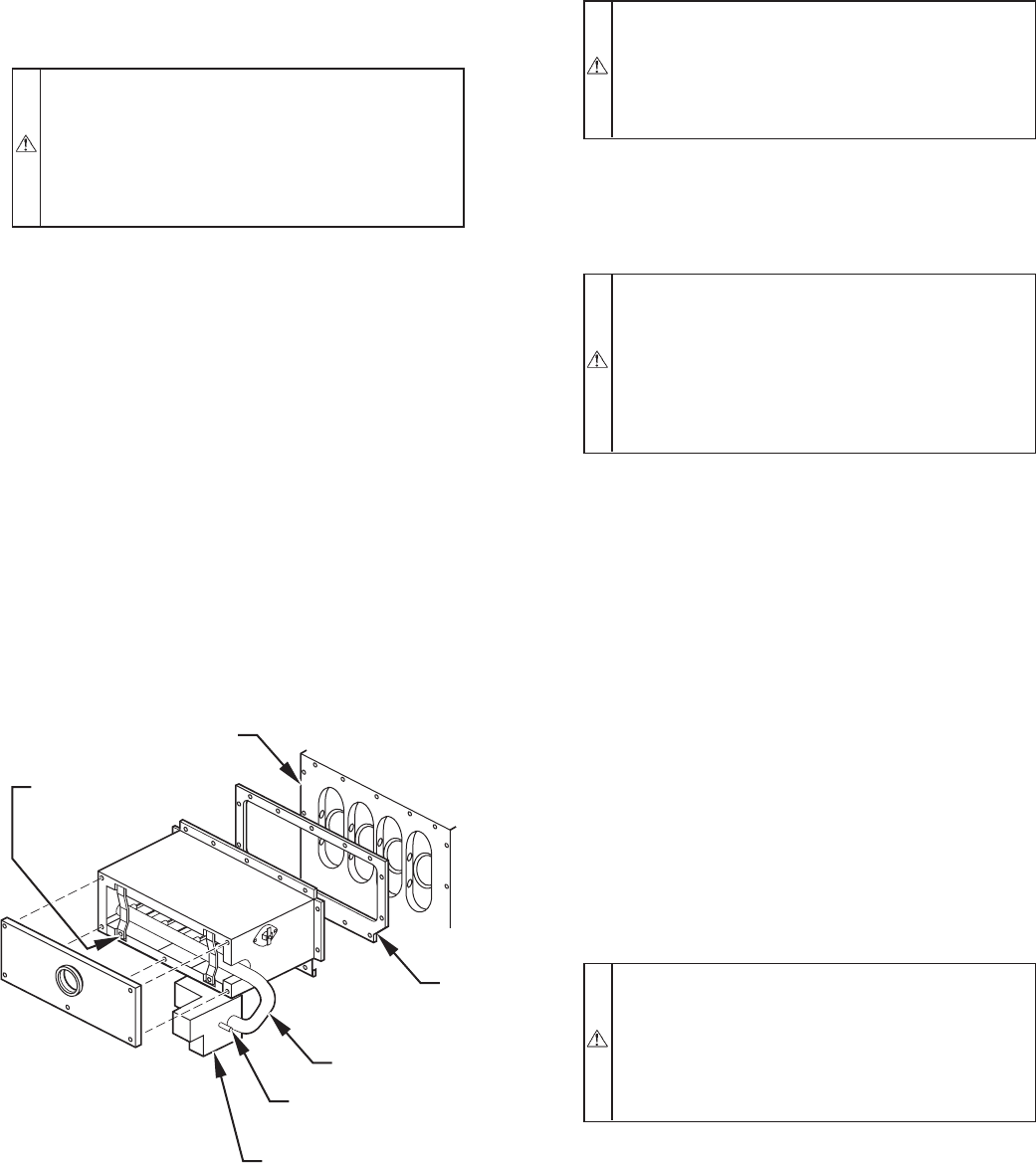

7. Remove screws that secure manifold to burner box. (See

Fig. 6.)

NOTE: Do not remove burner box from cell panel.

8. Remove manifold, orifices, and gas valve as 1 assembly.

9. Remove screws attaching burner assembly in burner box.

10. Remove burner assembly from burner box.

NOTE: All burners are attached to burner bracket and can be

removed as 1 assembly.

11. Clean burners with soft brush and vacuum.

12. Reinstall manifold, orifice, and gas valve assembly in

burner box. Ensure manifold seal grommet is installed

properly and burners fit over orifices.

13. Reconnect wires to gas valve. Refer to furnace wiring

diagram for proper wire location.

14. Reinstall burner box pressure tube to gas valve regulator

fitting.

15. Reinstall gas supply pipe to furnace gas control valve using

backup wrench on gas valve to prevent rotation and

improper orientation.

NOTE: Use propane gas resistant pipe dope to prevent gas leaks.

DO NOT use Teflon tape.

WARNING: FIRE, EXPLOSION, UNIT DAMAGE

HAZARD

Failure to follow this warning could result in property

damage, personal injury, or death.

Gas valve switch MUST be facing forward or tilted

slightly.

16. Replace burner box cover.

17. Turn on gas and electrical supplies to furnace.

18. Check for gas leaks.

WARNING: FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly could result

in serious injury, death or property damage.

Never test for gas leaks with an open flame. Use a

commercially available soap solution made specifically

for the detection of leaks to check all connections. A fire

or explosion may result causing property damage, per-

sonal injury or loss of life.

19. Replace main furnace door.

IV. CLEANING HEAT EXCHANGERS

The following items should be performed by a qualified service

technician.

A. Primary Heat Exchangers

If the heat exchangers get an accumulation of light dirt or dust on

the inside, they may be cleaned by the following procedure:

NOTE: If the heat exchangers get a heavy accumulation of soot

and carbon, both the primary and secondary heat exchangers

should be replaced rather than trying to clean them thoroughly due

to their intricate design. A build-up of soot and carbon indicates

that a problem exists which needs to be corrected, such as

improper adjustment of manifold pressure, insufficient or poor

quality combustion air, improper vent termination, incorrect size

or damaged manifold orifice(s), improper gas, or a restricted heat

exchanger (primary or secondary). Action must be taken to correct

the problem.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

CAUTION: ELECTRICAL SHOCK AND UNIT

DAMAGE HAZARD

Failure to follow this caution may result in minor

personal injury or furnace component damage.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and hazardous

operation.

3. Disconnect wires or connectors to flame rollout switch, gas

valve, igniter, and flame sensor.

4. Disconnect combustion-air intake pipe from intake housing.

5. Remove the pressure switch tube from intake housing.

Fig. 6—Burner Box Assembly

A02312

MANIFOLD

MOUNTING

SCREWS

MANIFOLD

GAS VALVE

REGULATOR

FITTING

GAS

CONTROL

VALVE

CELL

PANEL

GASKET

—5—

→

→

(52 pages)

(52 pages)

Comments to this Manuals