Bryant GAMA 331JAV User Manual Page 2

- Page / 24

- Table of contents

- BOOKMARKS

Rated. / 5. Based on customer reviews

2. Firmly touch a clean, unpainted, metal surface of the

furnace chassis which is close to the control. Tools held in

a person’s hand during grounding will be satisfactorily

discharged.

3. After touching the chassis you may proceed to service the

control or connecting wires as long as you do nothing that

recharges your body with static electricity (for example; DO

NOT move or shuffle your feet, DO NOT touch un-

grounded objects, etc.).

4. If you touch ungrounded objects (recharge your body with

static electricity), firmly touch furnace again before touch-

ing control or wires.

5. Use this procedure for installed and uninstalled (un-

grounded) furnaces.

6. Before removing a new control from its container, dis-

charge your body’s electrostatic charge to ground to protect

the control from damage. If the control is to be installed in

a furnace, follow items 1 through 5 before bringing the

control or yourself into contact with the furnace. Put all

used AND new controls into containers before touching

ungrounded objects.

7. An ESD service kit (available from commercial sources)

may also be used to prevent ESD damage.

INTRODUCTION

The model 331JAV Series B Furnace is available in sizes 60,000

through 100,000 Btuh input capacities.

The design of the downflow gas-fired furnace is A.G.A./C.G.A.

certified for natural and propane gases and for installation on

noncombustible flooring. The furnace is factory-shipped for use

with natural gas. The manufacturer’s accessory gas conversion kit

is required to convert furnace for use with propane gas.

These furnaces SHALL NOT be installed directly on carpeting,

tile, or any other combustible material other than wood flooring. In

downflow installations, the manufacturer’s accessory floor base

must be used when installed on combustible materials and wood

flooring. Special base is not required when this furnace is installed

on manufacturer’s Coil Assembly Part No. CD5 or CK5, or when

Coil Box Part No. KCAKC is used. This furnace is for installation

in alcoves, attics, crawlspaces, basements, closets, or utility rooms.

The design of this furnace line is not A.G.A./C.G.A. certified for

installation in mobile homes, recreation vehicles, or outdoors.

Before installing the furnace, refer to the current edition of the

NFGC and the NFPA 90B. Canadian installations must be installed

in accordance NSCNGPIC and all authorities having jurisdiction.

For a copy of the NFGC NFPA54/Z223.1, contact International

Approval Services U.S. Inc., 8501 E. Pleasant Valley Road,

Cleveland, OH 44131 or National Fire Protection Association Inc.,

Batterymarch Park, Quincy, MA 02269. For a copy of NFPA 90B,

contact National Fire Protection Association Inc., Batterymarch

Park, Quincy, MA 02269.

Before installing the furnace in Canada, refer to the current edition

of the NSCNGPIC. Contact Standards Department of Canadian

Gas Association, 55 Scarsdale Road, Don Mills, Ontario, Canada

M3B 2R3.

The duct system should be designed and sized according to

accepted national standards published by: Air Conditioning Con-

tractors Association (ACCA), Sheet Metal and Air Conditioning

Contractors National Association (SMACNA). Or consult the

Residential Systems Design Guidelines reference tables available

from your local distributor. The duct system should be sized to

handle the maximum CFM capabilities of the equipment at the

optimum design static pressure.

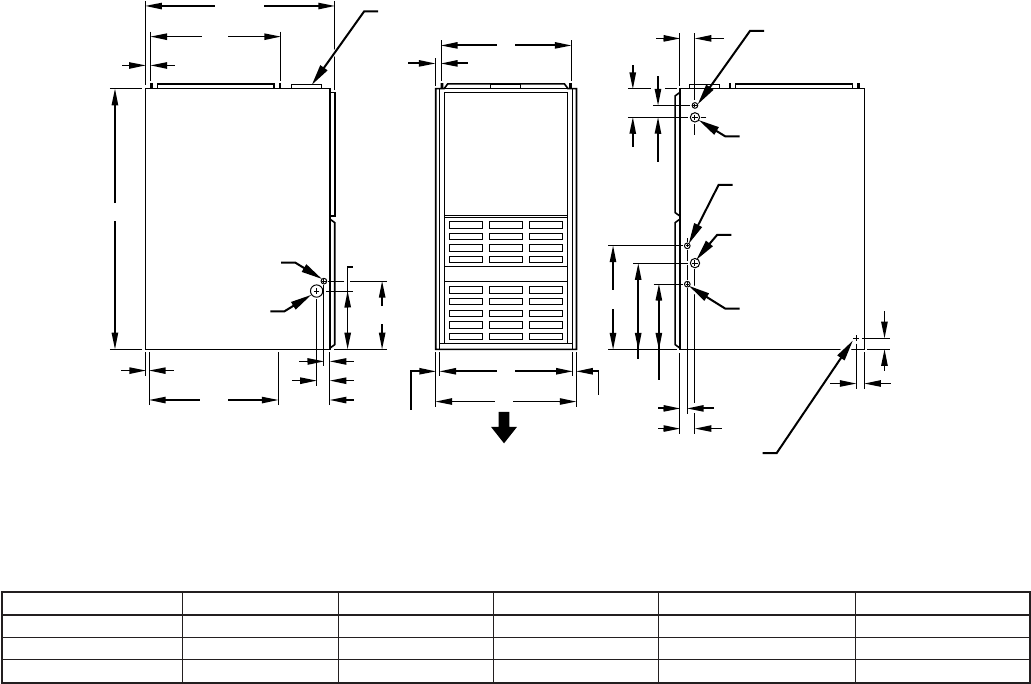

Fig. 1—Dimensional Drawing

A88324

4

3

⁄

16

″

2″

2

15

⁄

16

″

13

⁄

16

″

11

⁄

16

″

9

1

⁄

8

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

8

1

⁄

4

″

10

1

⁄

4

″

1

1

⁄

16

″

2

1

⁄

8

″

16

1

⁄

16

″

13

5

⁄

16

″

19″

11

⁄

16

″

13

⁄

16

″

11

⁄

16

″

20″

28

1

⁄

2

″

39

7

⁄

8

″

D

5

⁄

8

″ TYP

1

″ TYP

E

A

AIRFLOW

OUTLET

INLET

1

⁄

2

″ DIA

THERMOSTAT

WIRE ENTRY

7

⁄

8

″ DIA

ACCESSORY

7

⁄

8

″ DIA

ACCESSORY

DIMPLES TO DRILL HOLES

FOR HANGER BOLTS (4 PLACES)

IN HORIZONTAL POSITION

ADDITIONAL

7

⁄

8

″ DIA K.O. ARE

LOCATED IN THE TOP PLATE

AND BOTTOM PLATE

NOTE:

7

⁄

8

″ DIA HOLE

POWER ENTRY

1

1

⁄

2

″ DIA

R.H. GAS ENTRY

7

⁄

8

″ DIA

ACCESSORY

1

3

⁄

4

″ DIA HOLE

GAS ENTRY

VENT CONNECTION

TABLE 1—DIMENSIONS (IN.)

UNIT SIZE A D E VENT CONN SHIP. WT

036060 14-3/16 12-9/16 12-11/16 4 145

048080 17-1/2 15-7/8 16 4 154

060100 21 19-3/8 19-1/2 4 181

—2—

→

(12 pages)

(12 pages)

Comments to this Manuals